The field of smart materials has witnessed a paradigm-shifting advancement as researchers announce a dramatic reduction in the response time of magnetorheological (MR) fluids. This breakthrough promises to revolutionize applications ranging from automotive suspensions to medical prosthetics, where millisecond-level adjustments can mean the difference between optimal performance and system failure.

For decades, the sluggish response of MR fluids - typically ranging between 50 to 100 milliseconds - has constrained their use in high-performance applications. The new formulation developed by a multinational research team slashes this delay to an unprecedented 5 milliseconds, effectively eliminating the latency that previously limited real-time control systems.

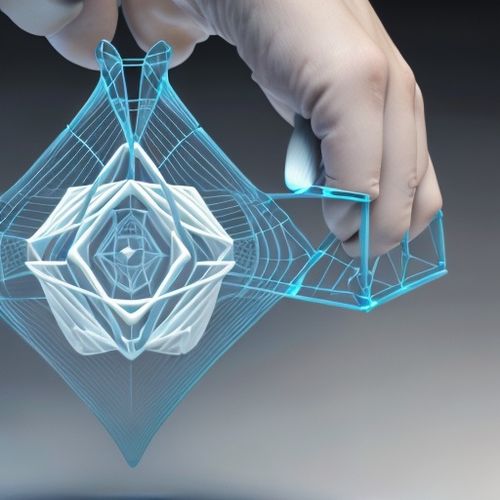

The science behind this leap forward involves a radical reengineering of both the ferromagnetic particles and carrier fluid. Traditional MR fluids employ micron-sized iron particles suspended in oil, creating a structure that requires time to align under magnetic fields. The breakthrough came through the implementation of precisely engineered nanoparticles with optimized surface chemistry, combined with a novel ionic liquid base that dramatically reduces viscous drag during particle alignment.

Dr. Elena Rodriguez, lead researcher at the Advanced Materials Laboratory in Barcelona, explains: "We've essentially created a system where particles behave like perfectly trained soldiers rather than a disorganized crowd. When the magnetic field activates, every particle knows exactly where to go and how to get there without getting in each other's way."

Industrial applications are already lining up to implement this technology. Major automotive manufacturers see immediate potential in adaptive suspension systems that can react to road conditions within a single wheel revolution. "At highway speeds, this could mean the difference between maintaining control and losing it when hitting a pothole," notes Michael Chen, chief engineer at a leading German automaker.

The medical field stands to benefit equally from this advancement. Prosthetic limb developers anticipate creating joints with near-instantaneous stiffness adjustment, allowing for more natural movement patterns. Rehabilitation devices could provide real-time resistance changes during therapy, adapting to a patient's muscle activation patterns with unprecedented precision.

Challenges remain in scaling up production while maintaining the exacting standards required for consistent performance. The nanoparticle synthesis process currently requires clean room conditions and precise temperature control, making large-volume manufacturing cost-prohibitive for some applications. However, several chemical engineering firms have already announced partnerships to develop more economical production methods.

Military applications have shown particular interest, with several defense contractors funding further research. Potential uses include rapidly adjustable body armor that stiffens upon impact and adaptive vibration damping systems for sensitive electronic equipment in combat vehicles. The near-instantaneous response time makes these applications feasible where previous MR fluid formulations would have been too slow.

As the technology matures, researchers anticipate discovering even more applications that were previously impossible. The team's next focus involves developing self-sensing variants that can provide feedback about their state while operating, creating truly intelligent systems. This could lead to structures that automatically reinforce themselves when detecting stress or machinery that adjusts its damping characteristics based on real-time performance data.

The breakthrough represents more than just an incremental improvement - it fundamentally changes what engineers can achieve with smart fluid systems. As production scales and costs decrease, we may soon see this technology emerge in consumer products, potentially transforming everything from household appliances to sporting goods. The era of instantaneous material adaptation has arrived.

By Thomas Roberts/Apr 19, 2025

By Michael Brown/Apr 19, 2025

By Victoria Gonzalez/Apr 19, 2025

By Benjamin Evans/Apr 19, 2025

By Eric Ward/Apr 19, 2025

By Emily Johnson/Apr 19, 2025

By David Anderson/Apr 19, 2025

By Olivia Reed/Apr 19, 2025

By Emma Thompson/Apr 19, 2025

By William Miller/Apr 19, 2025

By Laura Wilson/Apr 19, 2025

By Emma Thompson/Apr 19, 2025

By John Smith/Apr 19, 2025

By John Smith/Apr 19, 2025

By James Moore/Apr 19, 2025

By Michael Brown/Apr 19, 2025

By John Smith/Apr 19, 2025

By Noah Bell/Apr 19, 2025

By Emma Thompson/Apr 19, 2025

By Benjamin Evans/Apr 19, 2025